News & Events

News & Events

- Advertisement No. C/08/2024(02) - Written Test/Personal Discussion (11th Nov 2024) - POSTPONED

- NCB IC Event: Innovate Youth: Building Tomorrow's Entrepreneurs.

- PG Diploma Admission 2024-25 - Written Test & Interview Reg.-Round II

- List of selected candidates for admission to One Year Post Graduate Diploma in Cement Technology at NCB Ballabgarh for Session 2024-25

Consultancy services for getting NABL Accreditation as per ISO/IEC 17025:2017

Notice on Public Grievance

NCB – CCE EVENTS / Forthcoming Training Programmes

Ongoing Proficiency Testing Schemes

ONLINE Payment Facility

Steps for Online Payment through SB Collect

Last date for Submission of Technical Papers in 18th NCB International Conference & Exhibition extended to 31st August 2024

Last date for applying for National Awards in Indian Cement Industry 2022-24 is extended to 31st August 2024

Post Graduate Diploma in Cement Technology 2024-25 (Date Extended upto 15 July 2024)

NCB requires Lab Analysts, Junior Assistants, Senior Assistant and Designer on Direct Recruitment Basis

New Facilities added in Calibration Services

18th NCB International Conference - Call for Papers

Corrigendum - Compassionate Appointment in NCB for Group “C” & “D

Compassionate Appointment in NCB for Group “C” & “D

18th NCB International Conference, 27-29 Nov 2024 (Bulletin 1)

NCCBM to host 17th International Congress on Chemistry of Cement (ICCC) in 2027 in New Delhi

Facilities

X-RAY DIFFRACTOMETER (XRD)

X-ray diffractometery is an essential tool for rapid identification of minerals, compounds and other crystalline phases. This technique is safe, non-destructive and fast for routine automatic operation and has wide applications in cement and construction industries for:

- Mineralogical and phase analysis of raw materials, wastes and industrial by-products

- Burnability studies of cement raw mixes

- Identification of clinker mineral phases, semi-quantitative estimation and polymorphism of clinker phases

- Detection of free lime, periclase, quartz and any other undesired phase in clinker

- Cement quality and adulterants in cement

- Diagnostic studies on causes of scaling and build-ups in cement rotary kiln, coating in cement silos, cause of refractory lining failure, unstable kiln coating, ring formation and kiln shell corrosion

- Hydration studies of cement Investigations on damaged concrete structure

X-RAY FLUORESCENCE SPECTROMETER (XRF)

XRF (X-ray fluorescence) is a non-destructive analytical technique used to determine the elemental composition of materials. XRF analyzers determine the chemistry of a sample by measuring the fluorescent (or secondary) X-ray emitted from a sample when it is excited by a primary X-ray source.

X-Ray fluorescence is used in a wide range of applications, including:

- Cement production

- Research in igneous, sedimentary, and metamorphic petrology

- Soil surveys

- Mining (e.g., measuring the grade of ore)

- Ceramic and glass manufacturing

- Metallurgy (e.g., quality control)

- Environmental studies (e.g., analyses of particulate matter on air filters)

- Petroleum industry (e.g., sulfur content of crude oils and petroleum products)

- Chemical characterization of raw materials, additives, clinker, cement, pozzolanic materials, gypsum etc.

- Generally used for quality control on production of cement.

- Facility for bead preparation

SCANNING ELECTRON MICROSCOPE (SEM)

- High magnification (up to 2,00,000x) and high resolution (3-nm) microstructural, nanostructural investigations and elemental mapping of clinker, hydrated cement, aggregate, concrete etc.

- Point to pint chemical analysis by EDS.

- Clinker mineral phases, impact of incorporation of unconventional materials in cement raw mix and alternate fuels on clinker morphology and microstructure

- Study on cement hydration and precipitation of calcium hydroxide

- Effect of pozzolanic materials on C-S-H gel, pore structure investigation,

- Early detection of alkali silica reaction.

- Study of interfacial zone in concrete, deterioration in concrete due to aggressive environment etc.

OPTICAL MICROSCOPE (OM)

Optical microscope, has wide application in cement and construction industries, is equipped with state of art polarizing and stereoscopic microscope attached with image analyzer. Optical microscope is an important tool for quality evaluation of cement raw materials, fly ash, slag, clinker, coarse and fine aggregates and concrete samples. Thin and polished sections of rock, clinker and concrete are examined in transmitted and reflected light respectively. In-situ samples of concrete and rocks are evaluated in stereoscopic microscope. The salient features are as follows:

- Qualitative and quantitative assessment of raw materials.

- Morphological, mineralogical and granulometric analyses of sand, fly ash, slag, tailings etc

- Mineralogical and micro-structural features of clinker mineral phases such as alite,belite, aluminate, alumino-ferrite phases and glass.

- Percentage of free lime in clinker.

- Quality variation in clinker induced by process and operational parameters.

- Percentage of glass content in fly ash and slag

- Percentage and morphology of palerosphere and cenosphere in fly ash.

- Detailed petrographic investigations of coarse and fine aggregates.

- Rock classification by petrographic methods.

- Petro fabric analysis of rocks

- Petrographic analysis of rocks pertaining to geo-technical investigations

- Evaluation of different types of aggregates for alkali-silica reactivity (ASR) and alkali-carbonate reactivity (ACR) studies

- Detailed microscopic investigations of fire damaged concrete, petrographic evaluation of hydrated concrete and microstructural analysis of hardened concrete of various ages and environment.

- Petrographic analysis and Langlier equation of silt samples.

- Identification and classification of heavy minerals in sand and silt samples.

- Quantitative estimation of mica in sand, silt and soil.

- Setting up of optical microscopic laboratories and impart training on operation and maintenance

INDUCTIVE COUPLED PLASMA SPECTROMETER (ICP)

An advanced instrumental technique for determination of heavy and toxic elements present in raw materials and industrial by-products used in the manufacture of cement and other building materials

- Fully automatic, computerized and state-of-art equipment

- The estimation of heavy and toxic elements up to the range of ppb

- Rapid and simultaneous analysis of number of elements

- Investigation of leachability of heavy elements

FOURIER TRANSFORM IR SPECTROMETER

- Fully automatic, computerized and state-of-art equipment

- Determination of functional groups such as carbonate, sulphate, silicate, aluminate etc.

- Characterization of cements, admixtures and fuels

ADIABATIC BOMB CALORIMETER

- Computerized and fully automatic

- Determination of calorific value of coal and other fuels

ISOTHERMAL CALORIMETRY

Isothermal calorimetry is sensitive & versatile tool for studying the hydration process of cement.

- The shape of the heat flow vs time curve reflects the hydration process of cement

- The integrated heat flow time curve i.e the energy evolved is related to the extent of hydration

- Excellent experimental reproducibility

Typical cement Applications for Isothermal Calorimetry:

- Setting Time & Premature stiffening

- Effect of Contaminations

- Effect of Admixtures

- Temperature Dependency of Cement Hydration

- Quality Control

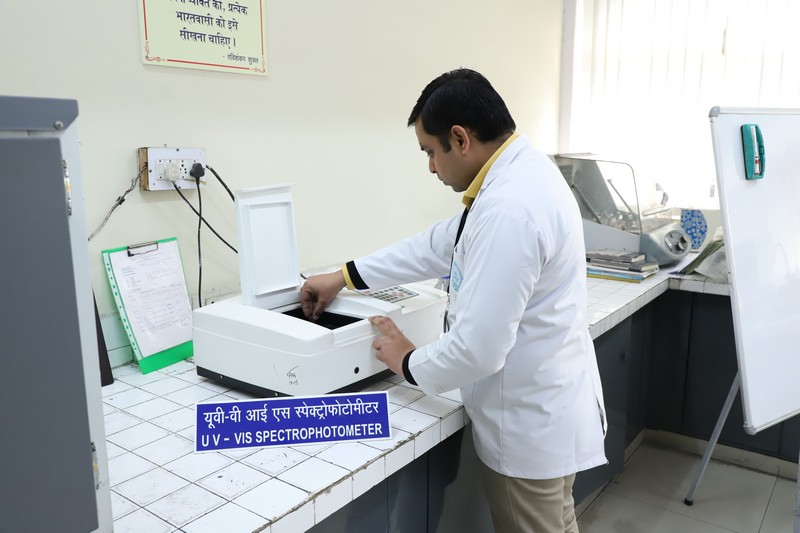

UV-VISIBLE SPECTROPHOTOMETER

- Fully automatic and rapid analysis of materials

- Determination of major and minor constituents in cement and other building materials

FLAME PHOMETER

- Equipment is used for estimation of alkalis such as Na2O and K2O present in raw materials, cement and other products

CHNS ANALYZER

The CHNS Analyzer find utility in determining the percentages of Carbon, Hydrogen, Nitrogen, Sulphur and Oxygen of organic compounds, based on the principle of "Dumas method" which involves the complete and instantaneous oxidation of the sample by "flash combustion".

It is used to study, a wide variety of sample types, including solids, liquids, volatile and viscous samples, in the fields of cement, building materials, pharmaceuticals, polymers, chemicals, environment, food and energy.

- Ultimate analysis of various types of fuels for carbon, hydrogen, nitrogen and sulphur

PH METER/ ION METER

- Used for determination of alkalinity and acidity by measuring pH value of the water and other solutions

DIFFERENTIAL THERMAL ANALYZER (DTA)

- Thermal behavior of raw materials, kiln feed and fuels up to 1450oC

- Determination of heat requirement (absorbed or evolved) in cal/gm during heating process

- Very effective in working out the compatibility of various raw materials and their thermal energy requirements in cement manufacture

- Polymorphism of clinker phases

- Hydration characteristics of cement

RAISING HEARTH FURNACE

- Raising hearth type furnace of the capacity up to 50 Kg is used for the bulk firing of the cement raw mixes

HIGH TEMPERATURE FURNACE

- Fully computerized furnaces

- Operational up to 1500oC

- Controlled heating and cooling systems

- Burnability studies and clinkerization

HEATING MICROSCOPE

- Used to study the high temperature behavior of raw materials, fuel ash, refractory, ceramic raw materials, glass, frits, enamels etc. refractory etc.

- Sintering studies

- Initial Deformation Temperature (IDT), spherical Temperature (ST), Hemisphere Temperature (HT) and Flow Temperature of fuel ash.

- The T max of the equipment is 1700oC.

REFRACTORINESS UNDER LOAD TESTING EQUIPMENT (RUL)

- This test measures the Refractoriness under load of refractory bricks as per IS: 1528 (Part-2)-2007.

- Equipment can measure the RUL Ta and RUL Te temperatures corresponding to 3 mm and 20 mm contraction of the specimen. The equipment can go as high as 2000oC.

PYROMETRIC CONE EQUIVALENT TESTING EQUIPMENT (PCE)

- This test measure the softening temperature of refractories, castables, mortars and any other material as per IS 1528 (pt 1):2007.

- The equipment measures the softening temperature by comparing the bending behaviour of test cone with that of standard cone.

- The maximum softening temperature of 1845oC corresponding to 38 cone as per ASTM cone can be measured.

PERMANENT LINEAR CHANGE TESTING EQUIPMENT (PLC)

- This test measures the Permanent Linear Change in the Refractory samples as per IS: 1528 (pt 6):2007.

- PLC is a design parameter and is very important while designing the lining schemes for their dimensional compatibilities, more so while working out thermal expansion joints and matching the overall longitudinal expansion of lining with that of kiln shell.

THERMAL SPALLING TEST EQUIPMENT

- This test measures the thermal spalling resistance of refractories as per IS 1528 (pt 3):2007.

- The equipment can measure the thermal spalling of three test specimen simultaneously by quenching the heated test specimens at 1300oC in water. The occurrence of first crack and number of heating and cooling cycles leading to about 20% specimen weight loss of its own is reported.

PARTICLE SIZE ANALYZER

- Fully automatic and rapid analysis of particle size distribution in cement and other powder samples

HARDGROOVE GRINDABILITY TEST APPARATUS

- Used for the determination of Hardgroove Grinding Index (HGI) of coal according to test procedures described in IS: 4433-1979 and ASTM D 409.

- Used to determine aggregate abrasion value

AUTOMATIC COMPRESSION TESTING MACHINES

- 50,100, 350, 1000 and 2000 KN capacities

- Compressive strength determination of cement mortar and concrete samples